Future-Proofing Your Sheet Metal Business with the Right Technology

Running a sheet metal business requires more than hard work. To succeed, you need the right tools. They must help you meet rising customer demands and stay efficient.

New technologies give businesses a chance to improve and prepare for future challenges. However, choosing the right technology can feel overwhelming.

This article will outline key tech upgrades for your business. With the right investment, you can boost productivity and cut waste. This will position your company for the future.

The Growing Importance of Technology in Sheet Metal Manufacturing

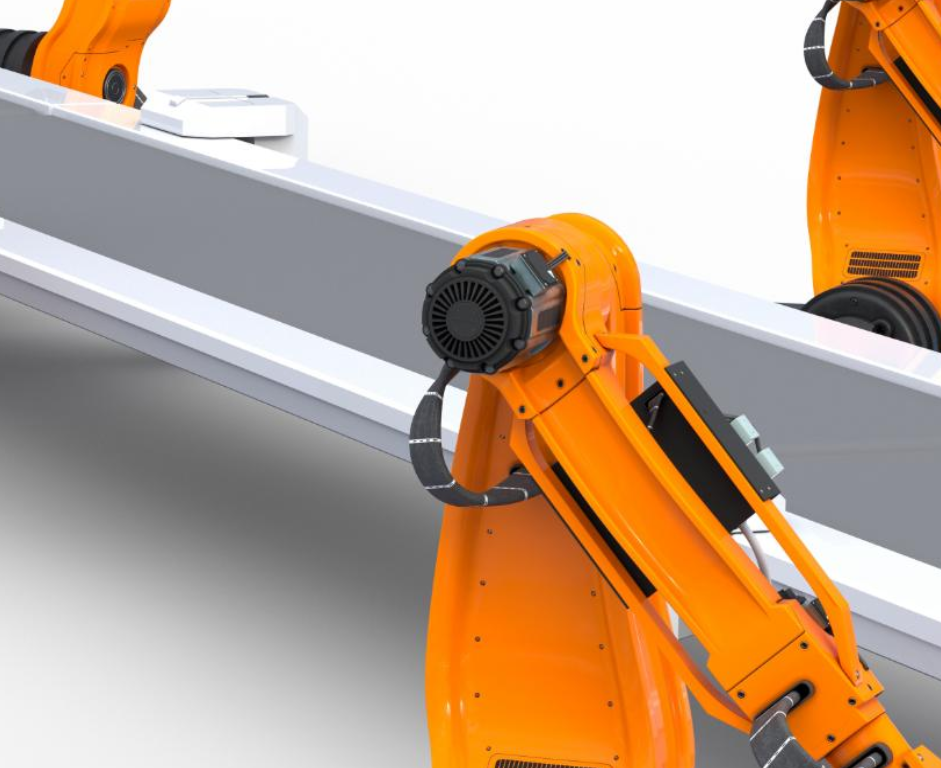

To meet rising customer demands, you must use modern machines and software to stay ahead. You also have tight deadlines. Automation is one of the key technologies driving change in the sheet metal industry.

Automated systems, like robotic arms and CNC machines, boost efficiency. They reduce waste and increase production precision. These systems can greatly reduce errors and rework. They will save time and money.

Digital integration is another major trend that can streamline your operations. Connect your machines and software. You can then track performance in real time. This will reduce downtime and enable faster, data-driven decisions.

Digital platforms improve planning, inventory tracking, and response times to customers. The result? Smoother workflows and higher customer satisfaction.

Key Technologies to Invest In

We’ve shown the technology’s importance. Now, let’s explore tools to future-proof your sheet metal business.

1. Press Brakes with Advanced Features

Press brakes are essential in bending and forming sheet metal. But traditional models can limit your business speed and precision. Upgrade to a modern press brake with advanced controls and automation. It will give you faster cycle times and better accuracy.

When it comes to buying a press brake, choosing the right supplier is critical. Buying from a reliable source ensures you get a machine. It must meet your current needs and be durable for future demands. Also, modern press brakes often have updated software. It gives you more flexibility as technology advances.

2. Laser Cutting Machines

Laser-cutting machines have revolutionized the processing of sheet metal. They provide precise cuts with minimal waste, making them ideal for complex projects. They work much faster than traditional methods. So, you can meet tight deadlines without sacrificing quality.

Also, many laser-cutting machines now have automation options. They include automatic material loading and unloading. This reduces the need for manual labor and speeds up production time. A laser-cutting machine can boost your output and cut labor costs.

3. CNC machines

CNC (Computer Numerical Control) machines have become standard in the industry. They offer precision, repeatability, and efficiency that manual machines cannot match. These machines can cut, drill, and mill. They are a versatile addition to your workshop.

CNC machines are very valuable. They can integrate with design software. This allows you to transition from design to production on time and with fewer errors. CNC machines ensure high quality, whether for custom parts or large batches.

How Automation Can Drive Growth

Automation is more than a way to cut labor costs. It helps your business grow. It does this by increasing capacity and output. It avoids hiring more staff. Automated solutions can help you keep production up as orders rise.

Automation can also improve worker safety. Machines can now handle many repetitive or dangerous tasks. This reduces injury risks and lets your employees focus on higher-level work. This protects your workforce and helps you maintain compliance with safety regulations.

Choosing the Right Software

Technology in the sheet metal industry is not about machines. The software you use can have a major effect on your operations. The right software can streamline everything. It can improve inventory management and project planning.

Enterprise Resource Planning (ERP) systems have gained popularity in sheet metal businesses. ERP software lets you manage all your operations from one platform. It gives you a clear view of your production processes, materials, and timelines. It helps you find issues before they become problems. This keeps projects on track.

Also, CAD software is essential. It turns customer designs into production-ready plans. Many engineers integrate modern machines with CAD programs. This eliminates the need for manual programming. This ensures higher accuracy and speeds up the entire production process.

Summing It Up

As industries continue to evolve, businesses must evolve with them. The ability to adapt to new tech will decide which companies thrive in the future. Smart, timely investments are key. In sheet metal manufacturing, this means being open to change. It also means positioning your business to enjoy future innovations. The tools you choose today will affect your success. This includes new machinery, software, and processes.